The popularity of matcha has been gaining! Starbucks Japan has launched a new menu using matcha “Matcha White Marble Frappuccino” since 6th Dec.

Besides, it is announced Starbucks Japan will launch an absolutely new matcha beverages. The ingredients matched to matcha for the new one is kept secret and the company provides those who bought the “Matcha White Marble Frappuccino” with some hint cards, where one of the ingredients used for the new is written.

All ingredients for the new matcha beverage will be opened in 22th Dec.

Not only Starbucks, many food companies has developed new matcha products according to the gaining popularity of matcha. For food industries, foaming is desirable or undesirable depending on the aimed design. As for matcha application, some occasions could be considered.

(1) Stabilizing foaming

Some purposes could be considered as follows

- Producing light or soft texture stably. (e.g. Matcha cream pudding )

- Requirement derived from the beverage characteristics. (e.g. matcha for tea ceremony)

- Optimizing the required quality and usage amount. (It might be possible to minimize the cost of ingredient with maintaining required qualities such as bright green color and unique aroma by controlling foaming.)

(2) Minimizing foaming

- Minimizing volume of products (e.g. condensed matcha paste or cream for industrial uses)

- Optimization of processing (e.g. minimizing the cost of high pressure loss accounting for increase in viscosity induced by foaming)

The volume of matcha foam depends on the size of particles according to the results reported by Sawamura et al.(2012). On the other hand, the stability of matcha foam seems to be independent to particle size because the degree of decline of foam volume is not so different among each sample, the decline rate of foam volume ranged between 69% and 82% [204].

Considering similar cases in food industries, meringue could be a similar foam. Meringue is a foam formed by protein, albumins. As for meringue, foaming is affected by various additives such as sugar and organic acid[426]. Ito et al.(1989) reported that addition of sugar and organic acid enhanced foaming of egg white.

Simple apparatus enable us to roughly evaluate stability of matcha foaming depending on additives. The volume of foam can be measured using measuring cylinder. The procedure of home experiment is as follows.

- Putting a spoon of matcha in a thermos.

- Pouring 100ml of solvents (here, water, 10%wt. sugar solution and lemon juice solution which contains 20ml of commercially available 100% lemon juice)

- Jiggling the thermos 150 bartender shakes for approx. 30 seconds.

- Pouring into the cylinder

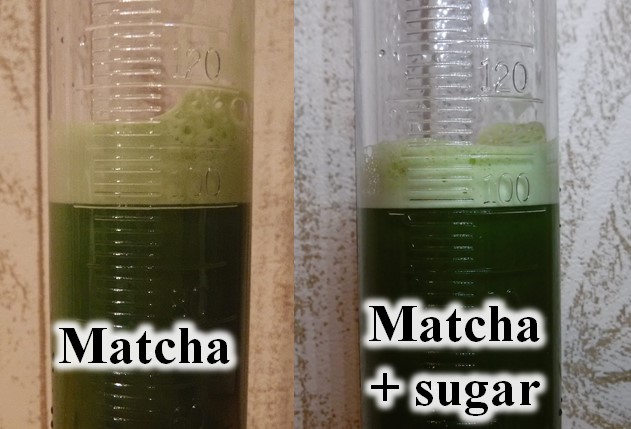

In this home experiment, the foam volume of matcha with sugar is lower than that of single matcha. There seems to be little difference in foam stability, which is change of foam volume with elapse time.

Foam stability of simple matcha. The volume of foam is approx. 7 ml.

Foam stability of matcha with sugar. The volume of foam is approx. 6ml.

The average bubble size of matcha with sugar might be look like smaller than that of simple matcha.

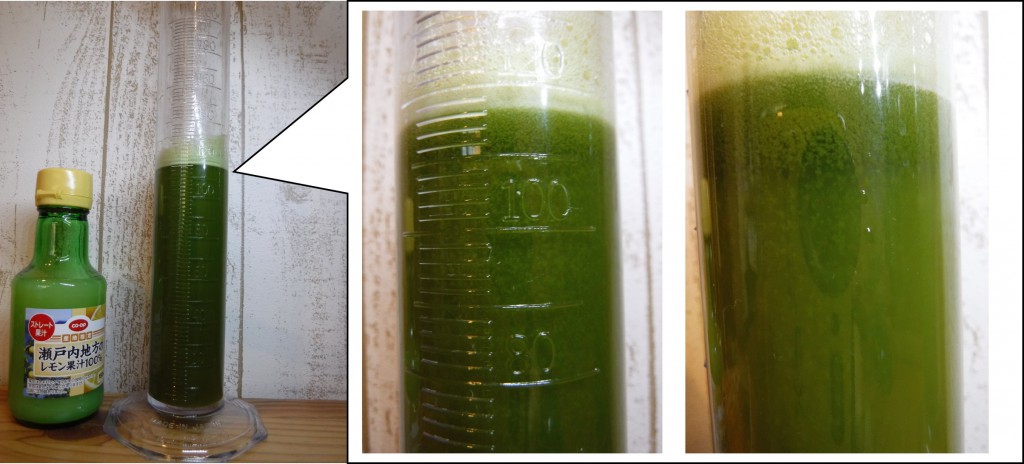

On the other hand, addition of lemon juice resulted in a unique change. Flocculation could be observed. The floc is speculated to consist of matcha particle, its aggregate and small bubble. Some flocs of matcha and air bubble floated up and accumulated under the foam.

The flocculation of matcha and air would be caused by lower negative charge of matcha particle. Acidic condition could neutralize negative charge of functional groups locating around matcha surface, resulting in decrease of repulsion derived from electrical double layer.

Amazingly the flocs of matcha-air mixture remains stably after a day. Unfortunately the acidic condition would cause the degradation of bright green color.

Acid-induced flocs remains floated on upper side of the suspension.

As reported by Poole (1989), the biopolymers having higher isoelectric point such as chitosan can enhance foaming. Based on the result, the addition of chitosan might enhance matcha foaming and viscosity increasing.

< References >

[204] Sawamura et al. (2012) : Foaming Property and Foam Diameter of Matcha Varies with Particle Size, Nippon Shokuhin Kagaku Kaishi, 59:109-114. (in Japanese, English abstract is available.)

[428] Poole, S. (1989) : The foam-enhancing properties of basic biopolymers, International Journal of Food Science Technology, 24:121-137.