Laser weeding, the idea of this technology has been discussed for long time since 1974[553]. At the period, Couch and Gangstad (1974) concluded the laser radiation could retard the plant growth due to suppression of photosynthesis. The ideas that laser direction could eliminate weed has been proposed since 2000s. Although the main technology of weed elimination using laser itself had been developed in 2000s, many technical regulations both in hardware and software have prevented farmers from their actual use of laser weeding. Fortunately, the recent developments in laser application and robotics have been implementing the robotic laser weeding.

Now some companies have already started to develop the concrete system of laser weeding. The German venture company “Escarda” has been trying to introduce its new system to manage laser weeding. The system detect weeds and distinguish all plants on the field by using multispectral sensors and their original algorithm, enabling the robot to direct the laser toward only weeds.

I hope a British enterprise “Small Robot Company” would also develop smaller automobile robots of laser weeding.

Laser radiation itself has been tested for weeding as shown on many movies updated on Youtube as follows.

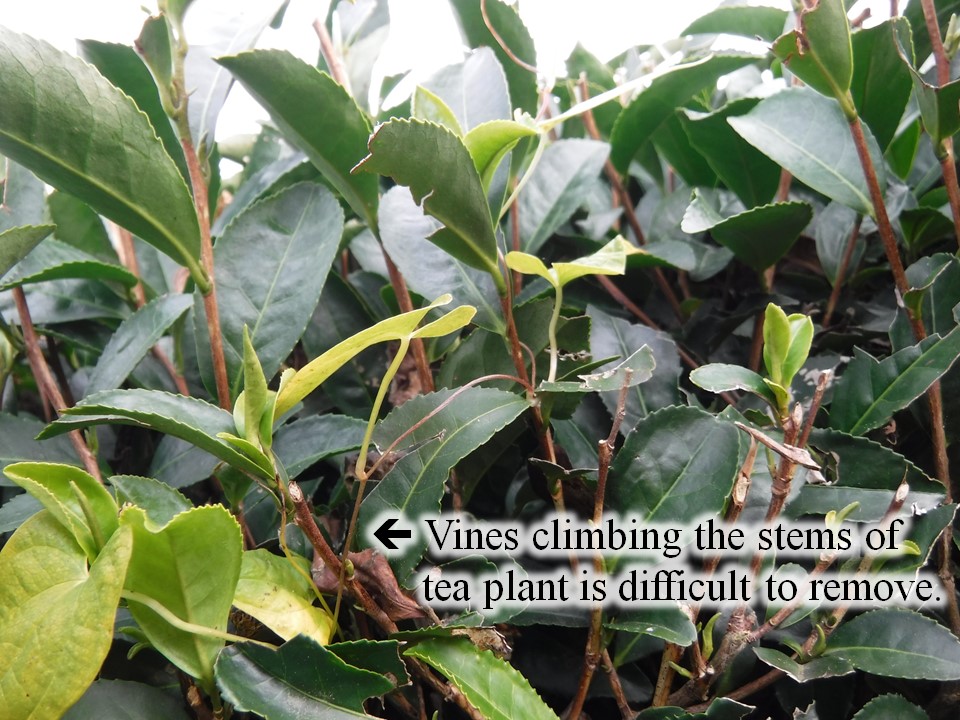

When trying to apply these technologies on organic tea farming, we should overcome two main issues. One is the robotic motion of laser weeder on the tea farm where the spaces free to machine is limited because of tea bushes and highly uneven surface of soil. Another one is weeds generated inside tea bushes. The weeds growing among tea plants inside the row of tea bushes are too difficult to remove. In general, tea farmers handpick these weeds, which is not efficient and too heavy labor for farmers.

As for the former issue, recent technologies may bring the solution. The combination of automatic vehicle of tea cultivation developed by Matsumoto Kiko Co. Ltd. and the attachment of hammer knife mower for tea cultivation vehicle developed by Ochiai Cutlery Manufacturing co., ltd.

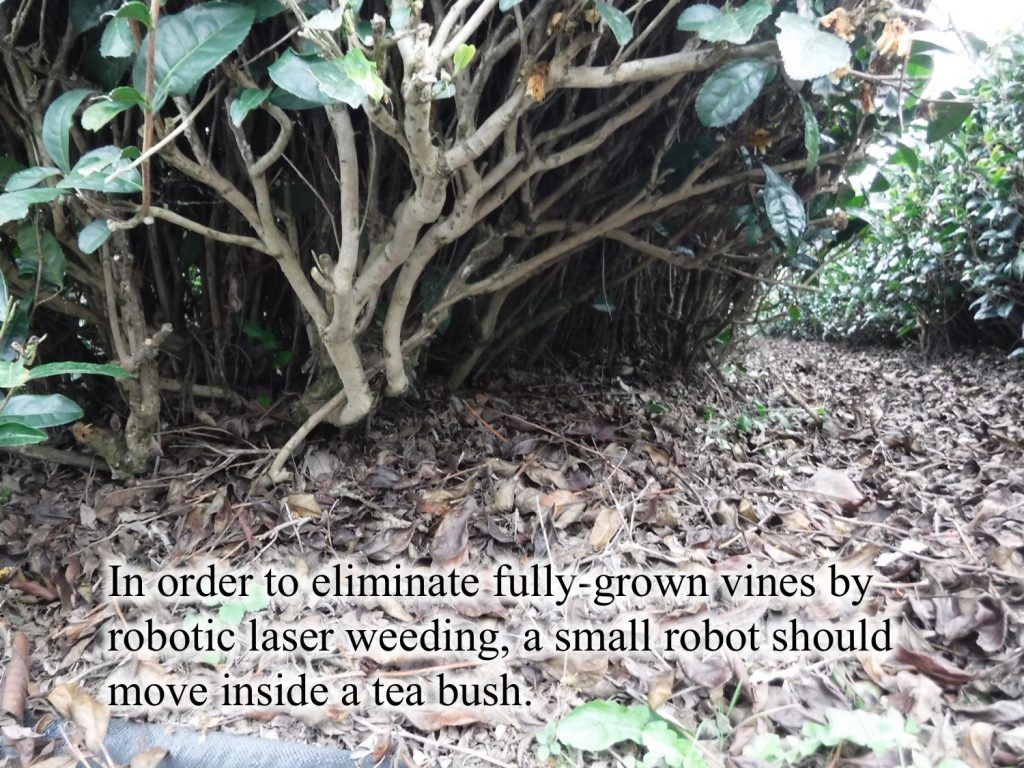

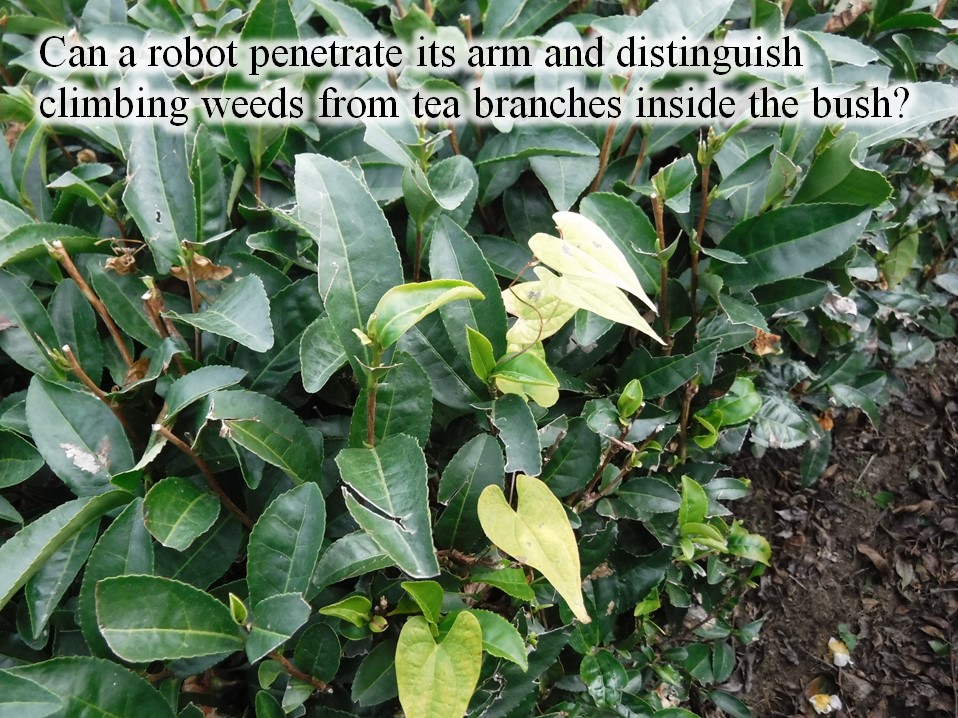

The problem of weeds among tea plants inside tea bushes row might be solved by the further development of laser weeding machine.  If the smaller automobile machine could move among the tea branches at the middle height of tea bushes, the machine could distinguish the weeds in tea bushes and radiate laser to eliminate.

If the smaller automobile machine could move among the tea branches at the middle height of tea bushes, the machine could distinguish the weeds in tea bushes and radiate laser to eliminate.

Otherwise, it might be also possible that the robot arms involving sensor and laser units could penetrate inside tea canopies and then distinguish and attack the weeds inside tea bushes.

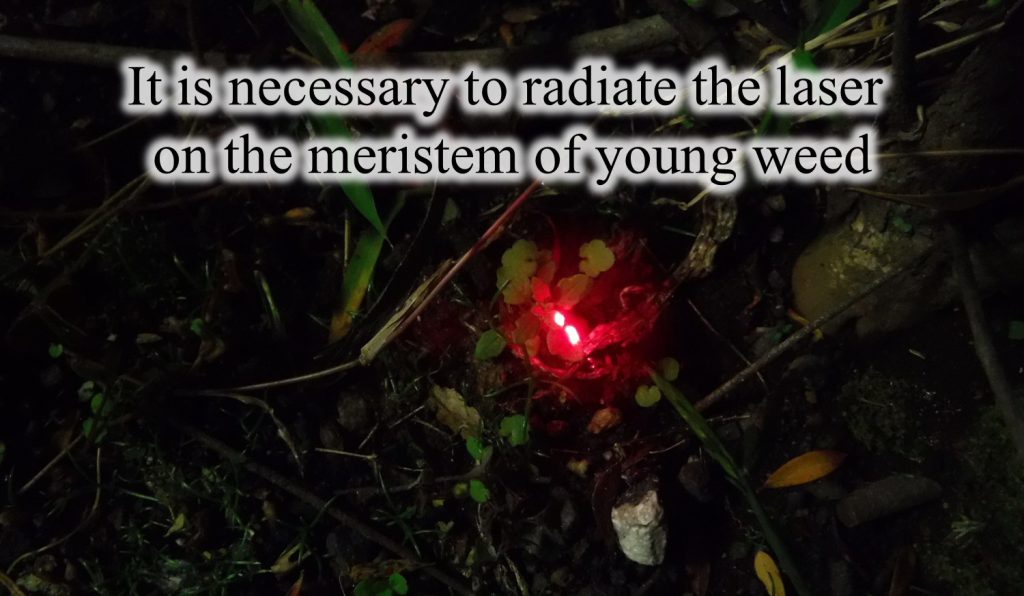

According to the results demonstrated by some researches, the laser beam should be directed toward the weeds’ meristem [538, 540, 542].

Laser radiation on the apical meristem seems to be effective to damage younger weeds, for example cotyledon stage. On the other hand, higher energy should be required for lethally-damaging the fully-grown vines because it is necessary to cut the stems of vines close to the soil. Damaging apical meristem against the fully grown vines might induce the growth of lateral buds, resulting in the more luxuriance of the vines. As described in Heisel et al.(2001), it is important to cut close to the soil surface to eliminate weed vines sufficiently [543].

It might be afraid that the weeding robot point its laser toward branches of tea plants. As for the discrimination of tea plants and weeds, various institutes have been trying to develop the software to distinguish weeds from tea plants[539, ]. Although now I don’t know how effective these software are, I hope and estimate the concrete system will be developed for its actual application.

The laser radiation onto the meristem of young weeds is effective.

On the other hand, the damaging meristem may not be effective for the sufficiently-grown weeds because the lethal damage of meristem could induce the growth of lateral shoots.

< References >

[538] Mathiassen S.K., Bak T., Christensen S., Kudsk P. (2006) : The Effect of Laser Treatment as a Weed Control Method, Biosystems Engineering, 95:497-505.

[539] Shah R., Lee W.S. (2015) : An approach to a laser weeding system for elimination of in-row weeds, Chapter in “Precision agriculture ‘15”, 307-312.

[540] Nadimi E.S., Andersson K.J., Jorgensen R.N., Maagaard J., Mathiassen S., Christensen S. (2009) : Designing, modeling and controlling a novel autonomous laser weeding system, 7th World Congress on Computers in Agriculture Conference Proceeding, 22-24.

[541] Ge Z., Wu W., Yu Y., Zhang R. (2013) : Design of Mechanical Arm for Laser Weeding Robot, Applied Mechanics and Materials, 347-350:834-838.

[542] Marx C., Barcikowski S., Hustedt M., Haferkamp H., Rath T. (2012) : Design and application of a weed damage model for laser-based weed control, Biosystems Engineering, 113:148-157.

[543] Heisel T., Schou J., Christensen S., Andreasen C. (2001) : Cutting weeds with a CO2 laser, Weed Research, 41:19-29.

[546] Cloutler D.C., van der Weide R.Y., Peruzzi A., Leblanc M.L. (2007) : Mechanical Weed Management, Non-chemical Weed Management, Chapter 8:111-134.

[547] Marx C., Perez P., Cesar J., Hustedt M., Barcikowski S., Haferkamp H., Rath T. (2012) : Investigations on the absorption and the application of laser radiation for weed control, Landtechnik, 67:95-101.